|

| November 03, 2020 | Volume 16 Issue 42 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Simple software creates complex wooden joints

Construction of useful wood objects sometimes requires complicated structures and ways to connect components together. Researchers in Japan have created a novel 3D design application to simplify the design process and also provide milling machine instructions to efficiently produce the designed components. The designs do not require nails or glue, meaning items made with this system can be easily assembled, disassembled, reused, repaired, or recycled.

Equal parts art and engineering, carpentry has figuratively and literally shaped the world around us. Yet despite its ubiquity, it's a difficult and time-consuming skill, leading to relatively high prices for hand-crafted wooden items like furniture. For this reason, much of the wooden furniture around us is often, at least to some degree, made by machines. Some machines can be highly automated and programmed with designs created on computers by human designers. This, in itself, can be a very technical and creative challenge that has been out of reach to many, until now.

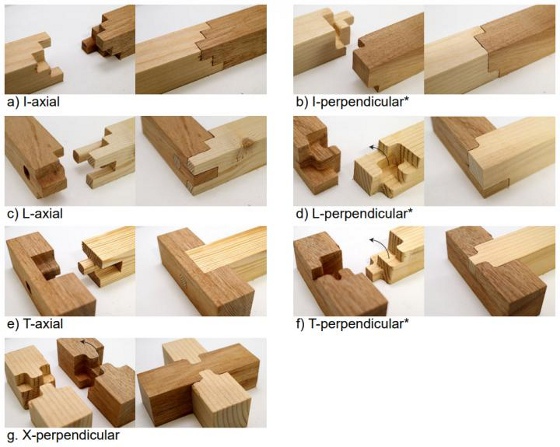

This image demonstrates how two pieces can be joined in seven unique -- and sometimes very complicated -- ways using the Tsugite software program. [Credit: © Larsson et al.]

Researchers from the Department of Creative Informatics at the University of Tokyo have created a 3D design application to make structural wooden components quickly, easily, and efficiently. They call it Tsugite, the Japanese word for joinery. Through a simple 3D interface, users with little or no prior experience in either woodworking or 3D design can create designs for functional wooden structures in minutes. These designs can then instruct milling machines to carve the structural components, which users can later piece together without the need for additional tools or adhesives, following on-screen instructions.

"Our intention was to make the art of joinery available to people without specific experience. When we tested the interface in a user study, people new to 3D modeling not only designed some complex structures, but also enjoyed doing so," said researcher Maria Larsson. "Tsugite is simple to use, as it guides users through the process one step at a time, starting with a gallery of existing designs that can then be modified for different purposes. More advanced users can jump straight to a manual editing mode for more freeform creativity."

Tsugite gives users a detailed view of wooden joints represented by what are known as voxels, essentially 3D pixels (in this case, small cubes). These voxels can be moved around at one end of a component to be joined, which automatically adjusts the voxels at the end of the corresponding component such that they are guaranteed to fit together tightly without the need for nails or glue. Two or more components can be joined, and the software algorithm will adjust all accordingly. Different colors inform the user about properties of the joints such as how easily they will slide together or problems such as potential weaknesses.

A feature that makes Tsugite unique is it will factor the fabrication process directly into the designs. This means that milling machines, which have physical limitations such as their degrees of freedom, tool size, and so on, are only given designs they are able to create. Similarly, one issue that has plagued users of 3D printers, which share a common ancestry with milling machines, is that software for 3D printers cannot always be sure how the machine itself will behave, which can lead to failed prints.

Another advantage of incorporating fabrication limitations into the design process is that Tsugite's underlying algorithms have an easier time navigating all the different possibilities they could present to users, as those that are physically impossible are simply not given as options. The researchers hope through further refinements and advancements that Tsugite can be scaled up to design not just furniture and small structures, but also entire buildings.

See "Tsugite: Interactive Design and Fabrication of Wood Joints (PDF link)," Proceedings of the 32nd Annual ACM Symposium on User Interface Software and Technology (UIST '20), by Maria Larsson, Hironori Yoshida, Nobuyuki Umetani, and Takeo Igarashi.

To learn more, go to the Tsugite page at http://ma-la.com/tsugite.html. NOTE: Designfax is not responsible for material downloaded from linked-to pages.

Source: University of Tokyo

Published November 2020

Rate this article

View our terms of use and privacy policy